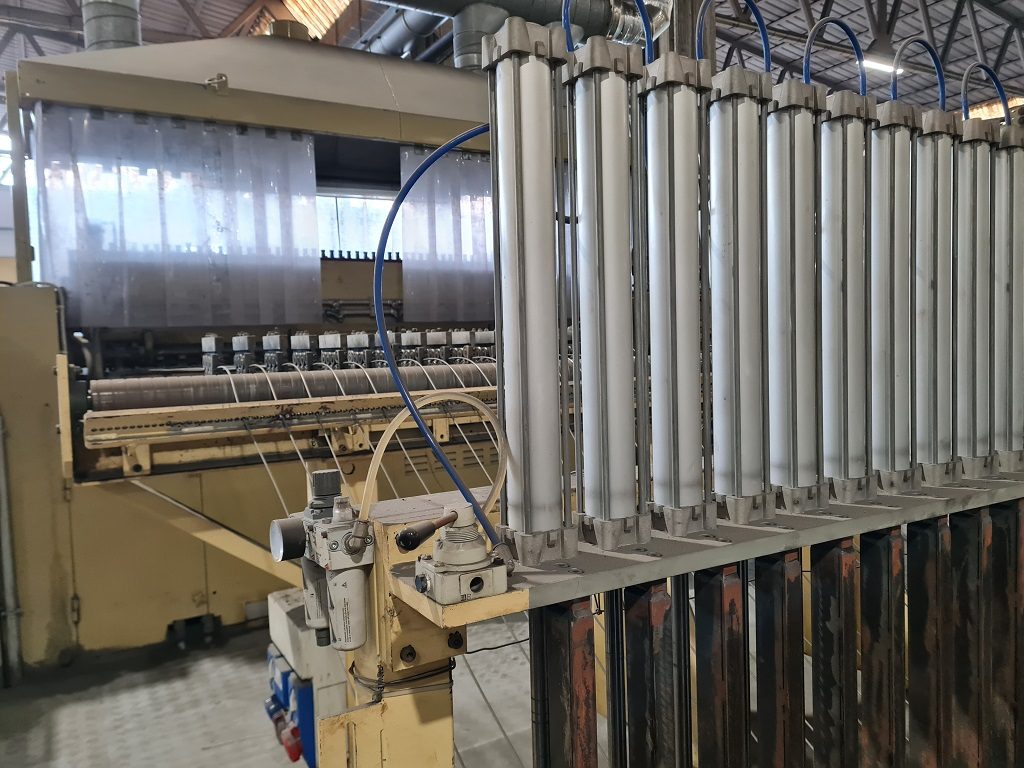

#666-380 Pratto Mesh Welder Model Starweld POB-36-2100; production of mesh panels and 3D/bent mesh panels; mesh width: 2100mm; wire dia. longitudinal + cross wires: 3-6mm; line wire spacing min.: 50mm; cross wire spacing min.: 25mm; SPM: up to 140; 5 x 250 KVA transformers; max. number line wires: 42 @ 50mm wire spacing; max. length of panels: 6000mm (20′); line consists of: payoff system; straightening-propulsion for longitudinal wires; loop LAR; powered straightening; cross wire payoff unit; cross wire loop; auto cross wire feed; welder; mesh trimming shear; mesh bending press; mesh ejection + stacking-turner; exit rolls

#666-418 EVG Model LGR/52 Wire Mesh Machine; min.-max. wire dia. longitudinal & cross wire: .148″ to .250″ (3.8-6.3mm); max. welding width: 52″; long. wire of coils: cross wire pre-cut hopper fed; min. line wire spacing: 1-1/2″; cross wire spacing: 3/4″ (.750″/19mm); strokes per min: 120 to 130 approx.; (4) 150 kVA transformers; double cut shear; programmable stacker; electrical-weld controls; in process of being rebuilt

#666-421 EVG Model WM3/65 Roll Mesh Take-up; width of fabric: 1700mm(65″); dia. of roll: 1000mm(40″); dia. of roll mandrel: 200mm; roll wire dia: 3-6mm; center height of mandrel: 800mm(31″); tension rollers; hydraulic pump unit; 8KW mandrel motor; operators pulpit; mesh roll discharge; no electrical controls; previously used on EVG GRS65 mesh welder |

#666-442 EVG Model GZF/85-HP; max. working width: 90″(2250mm); max. welding width: 85 (2137mm); min.-max. line & cross wire dia.: 1.0 to 3.0mm, line wire spacing: min. 12.5(1/2″); cross wire spacing: min.: 12.5mm(1/2″); line & cross wires from coils; SPM: 100 max. approx.; payoff back frame; line wire interlock device; line wire break detection; line wire straighteners; mesh torsion; edge trimming & slitting units; cross wire payoff; coil winder for rolls; drive motor: 20 KVA, 380V-50-3ph7

Click here to view videos:

https://www.youtube.com/watch?v=MYbvaln7IiM

https://www.youtube.com/watch?v=MfYfofBMjQQ

https://www.youtube.com/watch?v=oZqHaD2cUBY

https://www.youtube.com/watch?v=8-JQCwthi0k

https://www.youtube.com/watch?v=TH2Kmz6_tEw

NO LONGER AVAILABLE #666-453 Ideal FSD Mesh Welder; line + cross wire dia. min.-max.: 2.8mm-6.0mm (.118″-.236″); max. width: 1650mm (64.96″); max. working length: 3200mm (125.98″); mesh spacings: line wire min.: 25mm (1″); cross wire: 15mm (.590″); number of line wires max.: 25; strokes per min.: 80; line + cross wires from precut; producing panels; inline wire nibbler; stacker-turner unit; S-7 controls; 380V-50-3ph NO LONGER AVAILABLE

#666-472 EVG Model GZS-102 Welded Wire Mesh Line; Max. working width: 108″; Max. welding width: 102″ (2590mm); Wire dia. range line and cross wires: .078”-.196” (2mm-5mm); Line and cross wire spacings: 0,5″- 8″, in steps of 0.5″ or 1″ (12.5-25mm); Speed: 100 strokes per minute; payoff unit; cross wire payoff unit; line wire guides; line wire straighteners; GZS-102 welder; cross wire edge trimming; roll takeup; 400V-50 HZ

#666-479 EVG Model LGR/72-C Wire Mesh Welder; year of construction: 1998; wire dia. 2mm-6mm; cross wire pitch: 12.5mm stepless; line wire pitch: 25mm stepless; max. panel length 3mt; max. panel width: 1800mm; speed: 120 strokes/min., the tons then depend on the type of product (diameter of the wire, size of the mesh); a rough estimate stands at 3000 tons with 220 working days arrangement over 3 shifts

#666-484 ELEKTROPUNKT (Serbian Mfg.) Welded Wire Mesh Line; year 2021; Min.- Max. Welding width: 2150mm to 2500mm; Min. – Max. Working width: 2150mm; Min. – Max. Line Wire spacing: 100mm-150mm; Min.- Max. Cross Wire spacings: 100mm-250mm; Line and cross wire: Min. – Max. Wire Dia. 4-10 mm; Line wires: Coils; Cross wires: Pre-cut; Line consists of: Payoff rack for spools. (Spools available at additional cost), Line Wire guide, Line Wire straighteners, LARS Loop feed system, Mesh welder, Shear, Stacker-Turner, Electrical Controls-Drives, Electronic and drives manufactured by Fatek

#666-489 COMIT-SCHLATTER Wire Mesh Welding Line; For the production of mesh sheets for concrete reinforcing. Line and cross wires from bars. longitudinal wire dia.: 4-12mm; cross wire dia.: 4-12mm; max. number of longitudinal wires: 24 n.; min. longitudinal wire spacing: 100mm; cross wire spacing: 50-250mm; max. width of wire mesh: 2500mm; max. speed (strokes per min.): 120/min.; working speed: 120 strokes per min.; Line Wire Feeder Schlatter Type “ZG 24 LVR”; New in 2006 Welding Machine, Type CO.24; 6 new in 2006 transformers, each transformer 100KVA; Cross Wire Feeding System Type QS5+QMD; PLC SIEMENS S7; Turning and Stacking Unit Type RIB-6M

#666-490 Clifford Versa Welder Model VW1210 (Machine #XY-125-AC-1210); part dimension: width min.-max. Y axis: 100-1020mm; length: min.-max. X axis: 100-1220mm; welding capacity max.: 12mm x 12mm – 1 intersection; welding transformer: 125 kVA; number of stored programs: 85; number of weld programs: 50; jig loading: manual 2 station rotating table; welding system: AC parallel welding

#666-492 (2) Pratto Welded Wire Mesh Lines; Model Starweld POH-35-2500-42 (line 1); Model Starweld POBH-36-2500-51 (line 2); high performance mesh welding line designed to produce high quality wire mesh 3D fence panels including Eurofence and “V” shaped fence; equipped with bending unit that allows for precise shaping of wire mesh; mesh width: 2500 mm, distance between two outer most line wires: 2500 mm; line wire diameter range: 4 to 6 mm; cross wire diameter range: 4 to 8 mm; number of line wires maximum: 42 (line 1), 51 (line 2); single cross wire hopper fed; cross wire spacings: 50 – 500 infinitely programmable; line wire spacing: 50 mm, programmable in 50 mm steps; line wires from coils of wire; total power KW : 1250; voltage: 400v-3-50

TEMPORARILY NOT AVAILABLE #666-497 Tillos Model FEWEL 2500 3D Welded Wire Mesh Panel Line; fully automatic line + cross wire; mesh width: 2500mm; line + cross wire diameters: 3 to 5mm; line wire distance min.: 50mm; cross wire step: 12.5 steplessly; sheet length: 3000mm; number of line wires: 51; (2) Kuka robot arms; complete payoff system; 180 SPM; 380V-50cycle-3ph – TEMPORARILY NOT AVAILABLE

#666-498 Pratto Mesh Welding Line, model SW-PCBD-FA-2600; mesh width: 2600mm; min. line wire spacing: 50mm; min. cross wire spacing: 25mm; range of wires: diameters: 4-16mm; working SPM: 120; Power: 1250 KVA; line + cross wires from pre-cut bars

#666-500 Polish Engineering Welded Wire Mesh Machine; semi-automatic, line & cross wires from pre-cut; maximum welding width: 2500 mm; minimum – maximum wire diameter line and cross wires: 3 mm to 6 mm; maximum mesh length: 3000 mm, possible to extend; cross wire spacing minimum – maximum: 40 mm – 400 mm; line wire spacing minimum – maximum: 20 mm – 2000 mm; automatic line wire feeder with Servo motor; cascading power; power: 380 V , 50 HZ

#666-501 Schnell Mesh Line model BB 2500; Smart Mesh model; standard mesh; for the production of electro-welded mesh panels, powered by previously straightened bars, particularly efficient for its flexibility, simplicity and speed of adjustment and programming. min.-max. diameter longitudinal wire: 4-l2mm; min-max diameter transverse wires of pre-straightened wire: 4-l2mm; max. number of longitudinal wires: 24; pitch of longitudinal wires: 100-1S0; 150-200; 200-250 mm; no cross wires: 50-1.000 mm; max. welding speed: 120 welds/min; weldable material with maximum carbon concentration: 0,2%; tensile strength: 700N/mm; 400V, 50Hz, 600KVA; Production of BC sheets: 2500 mm, min-max width of the trellis (transverse length): 1250-2500mm, min-max length of crown trellis: 2000-9000 mm. ML Command Console: Control console equipped with a 12.1′ LCD screen for management and complete diagnosis of the installation. Equipped with a serial port, a USB port, an ethernet port for network connection with an external computer for remote assistance; BAB/ 2S0010T 9M longitudinal wire supply bench longitudinal wire storage bench Payload: 10 tons, length 9 meters; ALL-SA 2500 longitudinal Eyelash Feeder; Semi-automatic feeder for longitudinal wires with servomotor feed, width: 2500 mm; longitudinal wire pliers: 24; Mesh welder SR-CA 4-125-16/2500; 7 controls and positioning of the transverse wire, 6 transformers 125 kVA, 16 welding presses with force of 5 KN, 12 upper bridges for spacing 100-150mm, 8 upper decks for center distance 150-200mm, 6 upper decks for center distance 200-250 mm, 24 lower electrode holders equipped with electrodes and a double current cable; ATD 2500 automatic crossbar feeder; CAR Mesh Puller; Water Chiller cooling unit 60 I/min

#666-502 Schlatter Model MG12.0/6B; 48” Wire Mesh Welding Line, fully automatic; completely rebuilt, retrofitted with latest Schlatter technology in 1999, reconditioned, retrofitted new electrical controls 2021; max. welding width: 1250mm (48”); min.-max. wire diameter: 1.5 to 6mm; originally set up to run 1.9mm to 4.1mm wire; max. welding stroke speed: 120 SPM; min. cross wire spacings: 10 to 150/250mm approx.; min. line wire spacing: 50mm; crosswire – automatic cross wire feed system Syrocut unit; 3 transformers @ 70 KVA ea; 400 amps/phase, 2 transformers @ 400V; 23 payoff turntable stands; electrical controls Techvil-Siemens 7; shear for longitudinal wires; shear for cross wires; double hopper

#666-503 High capacity, fully automatic engineered mesh welding plant –

SUPERWELD 3800 – 5 line-3 cross /39 x 6-13mm